Bloomcraft Apparel’s 4 pillars are to deliver the best of quality in a shortest lead-time, maintaining price competitiveness, all while making the most efficient use of resources. Everything is built around these pillars of strength.

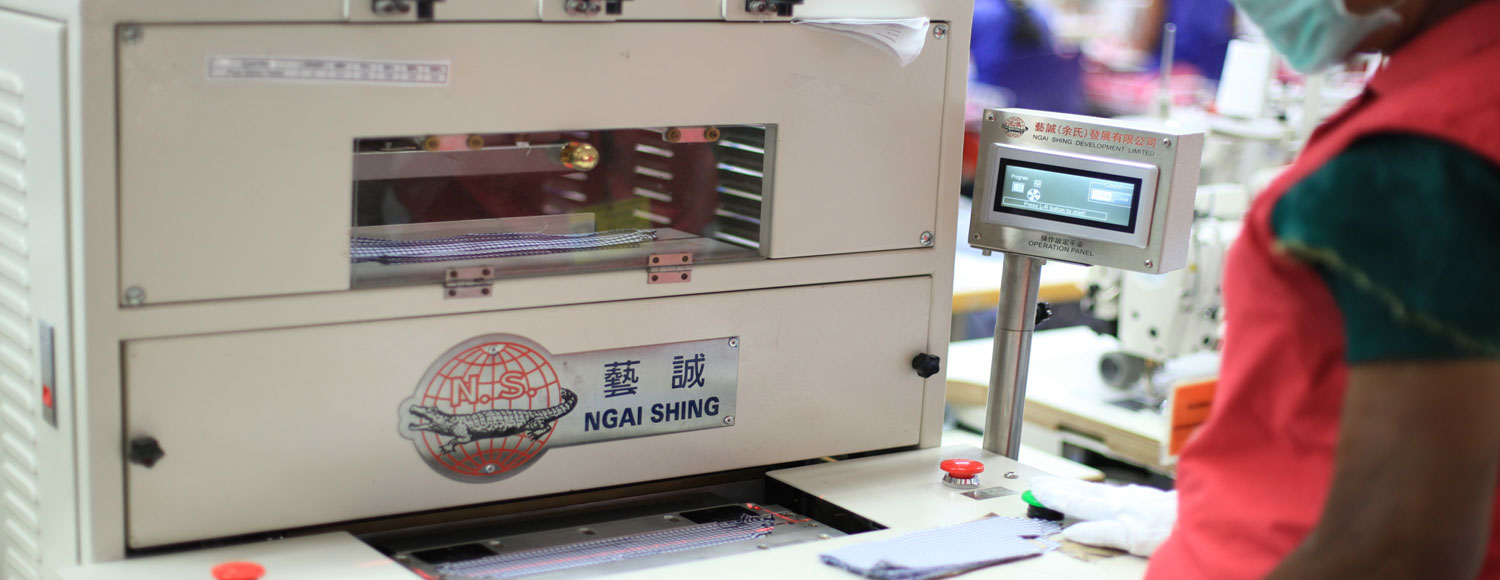

To achieve the best outcomes, vividly experienced personnel are employed with Gerber GTXL Automatic Cutter, Gerber Spreader, Die-Cutting, Triple Buck Carousel Hydraulic Fusing Press and other specialized machines.

Bloomcraft is equipped with Veit- FXDiamond machines, which ensures outstanding fusing results, PAFF laser guided machines for collar and cuff blocking.

Conveyor systems in the finishing lines, along with specialized machines for collar and cuff pressing, thread sucking and folding. Various stringent quality control measures are applied to keep a check on production.

Two ton wooden boiler for finishing which makes it effortless for us to deliver clean and crisp ironed garments. Facilities for any type of wash/ treatments are also available.

Sampling capacity of 150 garments a day which includes all background support of pattern making, pattern development, pattern correcting, grading, styling and forming tech-packs specified by the buyer.

In-house team, which designs CAD’s and develops fabric from world-class mills. We also design fabrics as per the latest trends and even develop the designs specified by the buyer.

Vertical integration with renowned Indian mills and have access to fabric collections from mills across India, China, Italy and Turkey.

Integration with the government to develop and train fresh tailors.

Follow 4 point AQL Audit System.

Advanced warehouse with facilities of fabric testing lab, fabric inspection, dark room, interlining roll cutting.

Thoroughly systemized processes implied in: trims storage, segregation and AQL inspection.

Confluence of various pre-production activities with high skilled sampling and technical team with all-round experience.

Highly resourceful training team, which provides thorough 21-day training with deftly, designed tests and training exercises, video and interaction sessions.

In-house dedicated team that caters to the development of new patterns, size specifications, styling, and fits: classic, slim, tailored etc.

Well-trained individuals work towards fine results with specialized machines for shirt making: feed of the arm, collar blocking, collar curve notcher, sleeve placket creasing, button wrapping and placket pressing.

We keep ourselves updated with the latest trends and have an updated library of collars, cuffs, fabrics and styles.